- Mindsailors

- Blog

- industrialdesign

- New product development costs

WHY ARE PRODUCT DEVELOPMENT COSTS HIGH?

It is not unusual for the process of creating a new product or service to be incredibly expensive, and it can often be difficult to determine the exact cost due to the many variables involved. When it comes to creative projects, such as developing a new technology or producing an original piece of art, putting a price tag on the work can be particularly challenging. This is because creative endeavors require time, effort, and sometimes even luck that cannot necessarily be quantified in terms of money. Creative projects also often involve unique risks that are not present with more traditional products, making it difficult to predict how much they might cost.

Furthermore, creative projects rely heavily on innovation and imagination which means there is no guarantee that what is produced will even end up being successful in the market. A great deal of research might go into a project before it’s launched but unexpected changes in direction or unanticipated technical issues could cause major delays and increased costs. As such, businesses must take into account not only the monetary costs associated with new product development but also the potential for unforeseen circumstances that could arise mid-project.

In addition to all these factors, there are certain intangible elements involved in creative work which make it hard to calculate its value accurately. The craftsmanship behind a piece of art or an inventive design cannot always be measured in dollars and cents; rather, its worth relies upon how well it resonates with people on an emotional level. All these unpredictable variables make it essential for businesses to plan ahead when tackling any kind of creative endeavour so they have plenty of time and resources available if problems arise during production.

Bad planning can lead to having to fix expensive mistakes in the later stages of product development, and these costly errors can be caused by a number of factors. One of the most common problems is an inadequate budget or timeline. If there is not enough time allocated for a project, then it may be necessary to make compromises that can lead to sub-par results. Similarly, if the budget is too tight then corners might be cut which could result in serious problems down the line. It is also possible for projects to suffer from scope creep which occurs when additional features or requirements are added without taking into account how long they will take and how much they will cost.

Another major source of costly mistakes during product development can arise from insufficient research and testing before launching the product. Without proper research and testing, products may end up being released with major flaws that were not identified until after it was revealed publicly. These issues can range from minor aesthetic discrepancies to major technical malfunctions that require costly fixes afterwards. Additionally, lack of customer feedback can also contribute towards errors since companies may assume certain features are desirable when they actually aren’t very popular with consumers.

Lastly, poor communication between stakeholders during a project can have disastrous consequences when it comes to product development costs because it leads to problems such as confusion over roles and responsibilities as well as missed deadlines due to miscommunication. Without clear lines of communication between everyone involved, important information might not get passed on which could cause serious delays and ultimately increase costs significantly.

In conclusion, bad planning during product development stages can often lead to expensive mistakes that need fixing later on in the process. Issues such as inadequate budgets and timelines, scope creep, insufficient research and testing, as well as poor communication between stakeholders all contribute towards this outcome by creating conditions where errors occur more easily and require more resources to rectify them afterwards.

The below product development costs analysis is based on "2022-2030 Report on Global Industrial Design Market by Player, Region, Type and Application" by Maia Research. Therefore it is not consistent with our Mindsailors Design Process and does not reflect the price offering of Mindsailors or the scope of services we provide. It is merely a reference to a global price range in new product development and the full scope of work that may need to be involved in delivering a new product to market.

If you wish to get our custom quote on your project you can contact us here.

IDEATION - PHASE 1 OF PRODUCT DEVELOPMENT

The ideation phase of new product development is a critical step in the process, where teams come together to brainstorm and conceptualize their ideas for a new product. This stage involves exploring various options, ranging from simple modifications to existing products to entirely new concepts. During this phase, teams will explore the potential of each idea and develop a plan for how it could be brought to life.

The ideation phase is typically fuelled by research and analysis of current trends, customer feedback, market insights, competitor strategies and industry standards. By studying these areas, businesses can gain valuable insight into what customers need or want and also identify areas of opportunity that they could capitalize on. Ideas are then generated based on these findings and evaluated according to their feasibility and potential profitability.

Ideas should be assessed using an objective approach which takes into consideration factors such as cost implications, timeframes, resources needed to bring the concept to life, potential risks involved and the level of competition in the market. Teams should also consider whether their idea meets any ethical or legal requirements before proceeding further with development. Once the best ideas have been identified from this assessment process, they can move on to the design stage.

In order for teams to create successful products during this phase, it’s important that stakeholders are kept up-to-date with progress made so far and actively collaborate towards achieving common goals. Creative sessions or workshops may be used as tools for encouraging collaboration between team members as well as generating actionable insights which can inform decisions made during development stages down the line. It’s also important that there is sufficient time allocated for creative problem solving during this phase so that all ideas can be explored properly before moving forward with implementation.

To sum up, ideation is an essential step in any new product development process - without it there would be no product! By taking a systematic approach towards exploring potential concepts and assessing them objectively before proceeding further with design & implementation stages, businesses can ensure they create successful products which meet customer needs while making positive contributions to their bottom line.

The average new product development costs in the ideation phase spans from $0 to $10,000.

INDUSTRIAL DESIGN - PHASE 2 OF NEW PRODUCT DEVELOPMENT

The Industrial Design phase of new product development is the process of taking the ideas generated in the ideation phase and bringing them to life. This involves creating a detailed design which captures all aspects of the product while ensuring it meets customer requirements, legal and ethical standards, as well as any other criteria set out during the ideation stage. During this phase, teams will refine their concepts through iterative testing and prototyping until they have achieved a design that is fit for purpose.

Designers must use a range of techniques when working on a product’s design in order to ensure it meets customer needs and expectations. These techniques can include but are not limited to: Human Factors Engineering (HFE), sketching, 3D modelling, rapid prototyping and computer aided industrial design (CAID). It’s important that designers use these tools effectively in order to create designs which are user-friendly, reliable and cost-effective.

At this stage, teams may also need to consider materials that could be used to construct their product such as plastics, metals or composites depending on their desired outcome. It’s important to select these materials carefully based on factors such as performance characteristics, production costs and environmental impacts so that they can bring down overall costs while maintaining quality standards. In addition to this, they should also keep an eye out for potential safety hazards when selecting components or materials which could cause harm or injury if used incorrectly by consumers.

To sum up, industrial design is an essential step in any new product development process as it captures all information necessary for turning an idea into reality while also allowing designers to test their proposals quickly without wasting resources. By taking a systematic approach towards refining concepts through iterative testing and prototyping teams can ensure they create successful products which meet customer needs while making positive contributions to their bottom line.

The average new product development costs in the industrial design phase spans from $5,000-15,000.

PROTOTYPING - PHASE 3 OF NEW PRODUCT DEVELOPMENT

Industrial Design teams will often use rapid prototyping technologies such as 3D printing or CNC machining in order to quickly produce models which represent the final product accurately enough for further testing or evaluation purposes. By using these methods early on in the process it allows teams to identify any improvements that need to be made before committing resources into full production runs - thereby reducing waste and errors associated with costly trial and error processes later down the line.

Prototyping is a crucial step in the new product development process as it allows teams to create physical models of proposed designs in order to test how they function before committing resources into full production runs. Through prototyping, teams can identify issues early on which may need resolving before finalizing the design or producing the final product.

When it comes to creating prototypes, there are a number of different methods and technologies available for teams to choose from depending on their desired outcome. For example, 3D printing is a popular choice for creating prototypes quickly at low cost thanks to its ability to produce geometrically complex shapes with high accuracy. This technique is also commonly used by industrial designers who require rapid prototyping capabilities during the early stages of product development. CNC machining provides another alternative for prototyping with its ability to produce parts accurately and quickly using computer guided operations.

Furthermore, there are experts involved in the process of prototyping who have the technical know-how necessary for fabricating prototypes successfully. These experts include engineers who have experience working with CAD software in order to create components that match specifications provided by industrial designers as well as technicians who can operate 3D printers and CNC machines accurately according to given instructions. Additionally, there are also specialists such as material scientists who can advise teams on suitable materials which could be used for specific projects based on cost considerations, performance characteristics and environmental impacts among other factors.

Overall, there are many different methods and technologies available when it comes to creating prototypes for new product development processes which should be taken into account when considering costs, production speeds and accuracy requirements among other factors. With the help of experienced professionals in various fields such as engineering or material science businesses can ensure they utilize these techniques effectively while ensuring they create successful products that meet customer needs while making positive contributions towards their bottom line.

The average new product development costs in the prototyping phase spans from $200-10,000 per iteration (per single prototype).

(1).webp)

ELECTRONICS ENGINEERING - PHASE 4 OF NEW PRODUCT DEVELOPMENT

Electronics engineering is the fourth phase of new product development and involves the design and manufacturing of electrical components for a given product. This could be anything from circuit boards to wiring harnesses and more, depending on the particular requirements of each project. In this phase, experienced electronics engineers are tasked with creating detailed schematics which accurately define the components needed in order to produce a functioning electronic system.

In order to create these systems, engineers must have a thorough knowledge of both analog and digital circuitry as well as experience in designing printed circuit boards (PCBs). PCBs provide an efficient way of connecting all the necessary components into a single system that can then be easily reproduced during mass production. Furthermore, specialists such as material scientists can also advise teams on suitable materials for use in PCBs once again considering factors such as cost, performance characteristics and environmental impacts.

When it comes to actually fabricating these components, companies typically rely on automation technologies such as pick-and-place machines to quickly assemble components onto PCBs according to their design schematics. Similarly, solder reflow ovens may also be used in order to accurately connect separate parts together while ensuring they are securely fastened in place. With these automated processes in place, teams can reduce errors associated with manual assembly processes while increasing speeds and accuracy significantly.

Finally, once these systems have been created they need to be tested thoroughly before entering into production runs. This is achieved through the use of dedicated testing equipment such as oscilloscopes which allow teams to monitor voltages and other parameters across different points on the board throughout its operation. By performing tests like this regularly it allows teams to identify any issues early on before committing resources into full production runs - thereby reducing waste and errors associated with costly trial and error processes later down the line.

Overall, electronics engineering plays a big role in modern product development processes due largely thanks to its ability to enable functionality beyond what was previously possible using mechanical or non-electronic solutions. With the help of experienced professionals in various fields such as engineering or material science businesses can ensure they utilize these techniques effectively while ensuring they create successful products that meet customer needs while making positive contributions towards their bottom line.

The average new product development costs in the electronics engineering phase spans from $4,000-40,000.

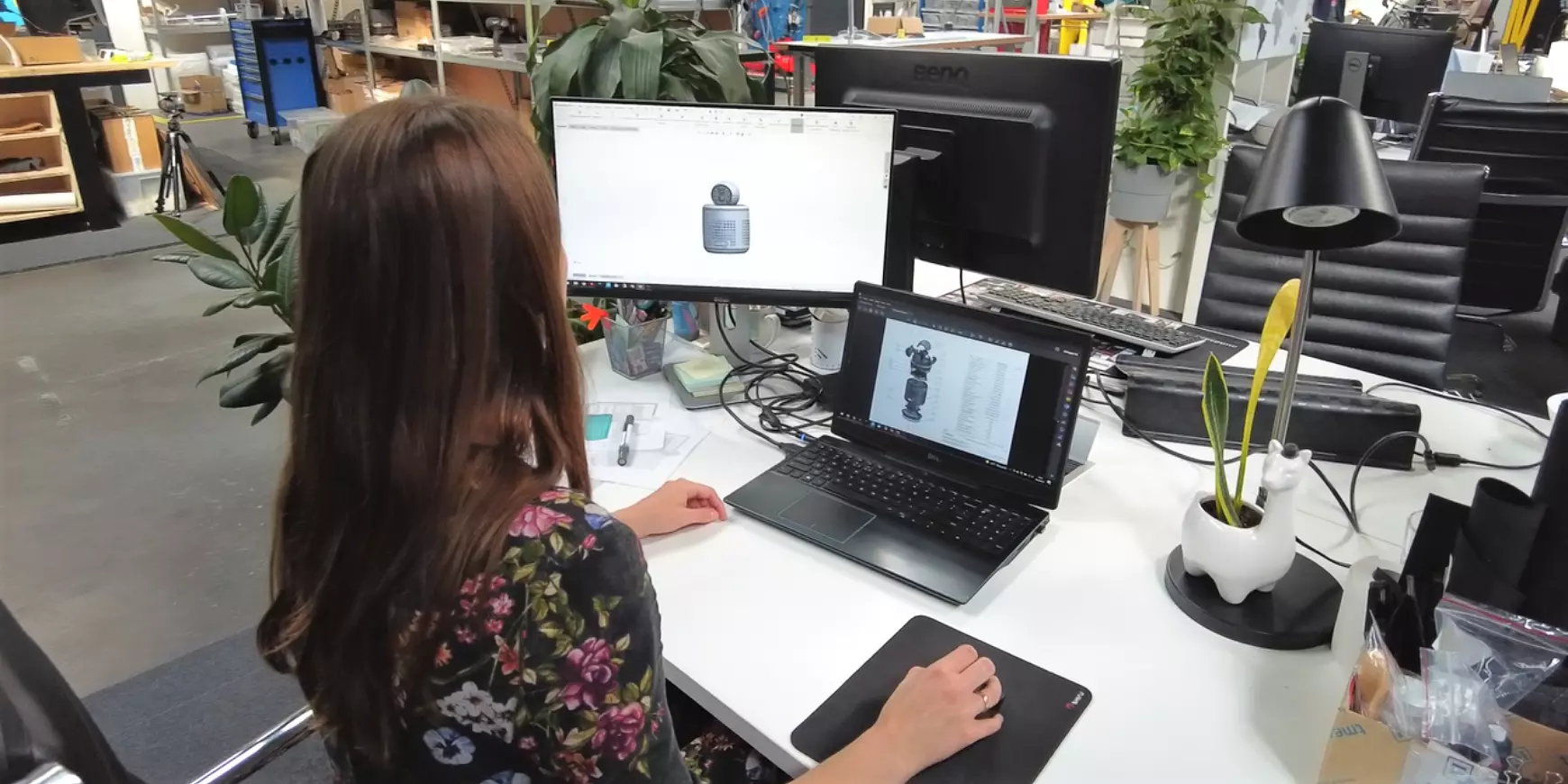

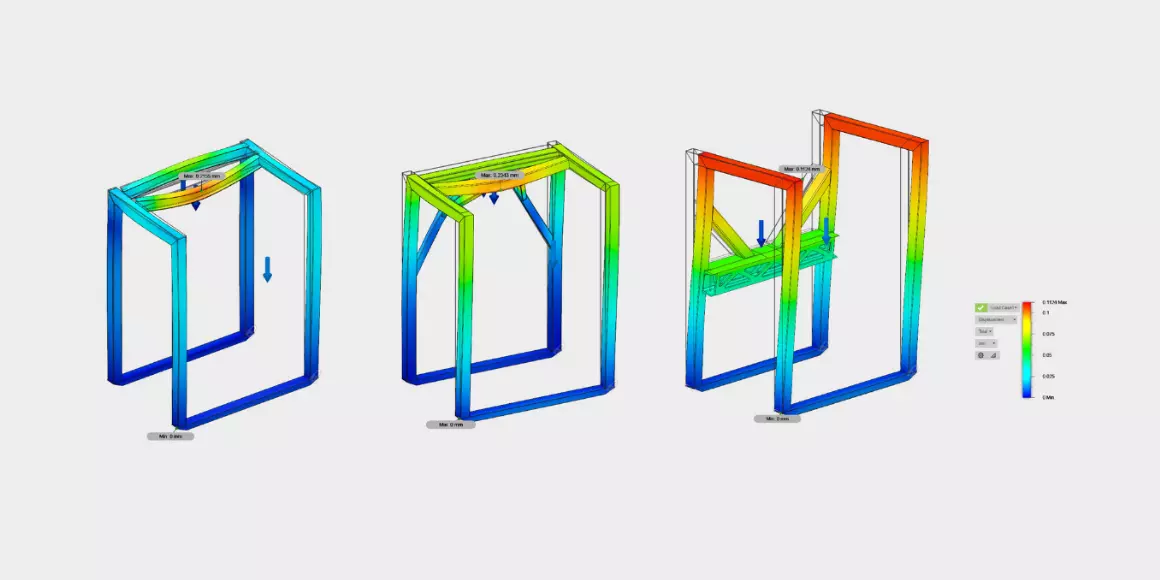

MECHANICAL ENGINEERING - PHASE 5 OF NEW PRODUCT DEVELOPMENT

Mechanical engineering is the fifth phase of new product development and deals with the design and manufacturing of mechanical components for a given product. These components could range from gears, to frames, to motors and more - all depending on the particular requirements of the project. In this phase, experienced mechanical engineers are tasked with creating detailed designs which accurately define the components needed in order to produce a functioning system.

Mechanical engineering requires an extensive knowledge of both engineering principles as well as materials science in order to accurately design components that will withstand any potential stresses placed upon them during use. To create these components engineers must be adept at using 3D modeling software such as SolidWorks or Autodesk Fusion 360 which allow them to create intricate models of their parts before progressing into manufacturing processes. Furthermore, due to its complexity it is important that engineers are able to effectively collaborate with electrical and software engineers in order to successfully integrate all components into a single system.

Once teams have successfully designed their systems they must decide how best to manufacture them. This decision process involves considering factors such as cost, performance characteristics and environmental impacts when selecting suitable materials for each component. Once the materials have been chosen teams can then decide between a multitude of different manufacturing processes such as casting, forging or 3D printing depending on their individual needs. Similarly specialist technologies such as Additive Manufacturing may also be employed if certain conditions are met such as low-volume production runs or customised parts; again depending on individual requirements.

Finally, once these systems have been created they must once again be tested thoroughly before entering into production runs - this time focusing on any mechanical related issues that may arise from usage scenarios. With the help of dedicated testing equipment such as force transducers teams can ensure their products meet any necessary safety regulations while enduring normal wear and tear over extended periods of time with minimal maintenance required.

Overall, mechanical engineering plays an integral role in modern product development processes due largely thanks to its ability to enable what was previously impossible using electrical solutions alone. With the help of experienced professionals in various fields such as engineering or material science businesses can ensure they utilize these techniques effectively while ensuring they create successful products that meet customer needs while making positive contributions towards their bottom line.

The average new product development costs in the mechanical engineering phase spans from $4,000-40,000.

TESTING AND CERTIFICATION - PHASE 6 OF NEW PRODUCT DEVELOPMENT

The sixth phase of new product development is the testing and certification stage. This step is crucial in ensuring that a product meets all necessary safety regulations, requirements and performance standards before being released to the public. In order to pass these tests, products must be tested by both third-party organizations as well as expert reviewers.

Third-party organizations such as Underwriters Laboratories (UL) provide rigorous testing services which ensure that all safety related aspects of a product are compliant with industry standards. These types of testing can range from electrical shock hazards to fire risks or mechanical failure points. During these tests, experts will evaluate all aspects of a product's design and construction in order to guarantee it performs safely according to its intended purpose. Depending on the specific requirements for a given product UL may also perform supplementary tests such as power line interference or magnetic field emissions in order to identify any potential issues before they become serious problems.

In addition to these tests, products may also require certifications from other third-party institutions such as the FCC (Federal Communications Commission) or IC (Industry Canada). These certifications help verify that products meet certain technical regulations such as wireless frequencies or emission levels before entering into public use. It is important for companies releasing new products to obtain these certifications in order to ensure their devices comply with all applicable laws and regulations within their countries marketplace.

Finally, expert reviewers are often employed in order to assess a product's overall usability and quality of design before it enters into production runs. These reviewers typically have extensive experience within the industry they are evaluating and can provide thorough feedback on any features requiring improvement or changes prior to launch. Companies can benefit greatly from using expert reviewers early on in their development processes as this feedback can help them refine any issues quickly without having them cost too much time or money during later phases when pressures begin to mount closer towards launch dates.

.webp)

Overall, the testing and certification phase plays an essential role in bringing successful new products into marketplaces around the world by providing businesses with an extra layer of assurance that their products comply with industry standards while simultaneously delivering value for customers through increased safety and reliability guarantees. By utilizing various third-party organizations such as UL, FCC or IC; along with the insight provided by experienced expert reviewers; companies can increase their chances of creating successful products that meet customer needs while making positive contributions towards their bottom line.

The testing and certification phase plays an essential role in bringing successful new products into markets around the world. Depending on the country, region or marketplace that a product is being released in, different certifications may be required from third-party institutions.

In Europe, the CE mark is a mandatory marking for many products in order to demonstrate compliance with all relevant European Union directives. This mark serves as a guarantee to consumers and customers alike that products meet all applicable health, safety and environmental protection requirements for use within the European Economic Area (EEA). This certification also helps ensure that products are safe to use, operate within legal radio frequencies, have energy efficiency labels and adhere to any specific chemical content regulations before entering European markets.

In the United States of America, the FCC (Federal Communications Commission) offers various certifications which help verify that products comply with technical regulations such as wireless frequencies or emission levels before entering into public use. These certifications cover a wide range of electronic equipment and components including everything from cellular phones and tablets to Bluetooth devices and vehicle audio systems. Companies wanting their products sold in US markets should familiarize themselves with these guidelines in order to ensure they are compliant prior to launching their devices into public consumption.

Canada has similar certification requirements for many types of electronics which must be fulfilled from an accredited organization called Industry Canada (IC). Products such as wireless routers, satellite antennas or any other device operating on radio frequencies must undergo approval tests conducted by IC in order to gain certification for entry into Canadian marketplaces. In addition to this approval process, IC also provides guidance towards regulatory compliance standards for telecommunications equipment used by businesses throughout Canada.

Finally, Australia has its own set of safety standards which are managed by Standards Australia; an independent non-profit organization responsible for setting industry wide benchmarks across many fields including engineering and technology. All manufacturers wishing to sell their products within Australian borders must have them tested by accredited laboratories designated by Standards Australia before they can be released publicly. This step helps ensure that all electronics comply with necessary safety regulations while providing confidence that the items will perform safely according to their intended purposes when used by consumers within Australia.

Overall, it is important for businesses worldwide to understand what certifications are required when releasing new products into different markets in order to protect both themselves as well as their customers from potential harm or danger caused by faulty equipment or poor design choices prior to launch dates. By leveraging the services provided by third-party organizations such as Underwriters Laboratories (UL), Federal Communications Commission (FCC) or Industry Canada (IC); along with expert reviews; companies can increase their chances of ensucessfully launching new products into markets around the world. Doing so, however, may involve additional costs which should be factored into any new product development budget.

The average new product development costs in the testing and certification phase spans from $5,000-50,000.

PACKAGING DESIGN - PHASE 7 OF NEW PRODUCT DEVELOPMENT

Packaging design is an essential part of the new product development process and involves creating a marketable display of a product. This phase typically follows the testing and certification stage and involves considering various factors such as target audience, product size and shape, legal requirements, safety standards, ease of transport, customer appeal and perceived value. Expert designers must collaborate to bring each element together into a cohesive package that reflects both the brand identity and purpose of the product.

One of the first steps in packaging design is to research targeted audiences to gain insight into their preferences for colors, logos, shapes, materials and other aesthetic elements. This step helps ensure that the final packaging design will be recognizable to consumers while still being distinctive enough to stand out from competitors on store shelves. It also allows brands to tailor their products towards different markets or demographics by making minor adjustments such as changing color schemes or adding localized language attributes.

Another important factor when it comes to packaging design is choosing materials which will provide sufficient protection for a given product while still allowing for proper visibility in displays or racks. Many companies use plastic containers for electronic items due to its durability and lightweight properties; however glass jars can often be used effectively with food items to allow customers to see what they are buying before making a purchase. Additionally foam inserts can be used inside boxes or cases in order to secure fragile items during transport so they arrive unscathed at their destination.

Furthermore, some industries are subject to additional regulations when it comes to designing packaging; such as industry specific labeling laws or warning symbols indicating potential hazards associated with using certain products. Companies must familiarize themselves with any applicable guidelines before releasing finished packages into distribution channels as failure to do so could result in expensive fines or even recalls due lack of compliance with relevant laws.

Experts involved in packaging design may include structural engineers who determine how best to protect products during shipping cycles; graphic designers responsible for choosing fonts, colors and images; marketing specialists who analyze consumer trends; copywriters who create clever slogans; lawyers specializing in regulatory compliance issues; production managers who oversee equipment setup/operation timing; industrial designers responsible for shape/size selection; cost analysts who evaluate expenditures associated with producing/shipping packages; sales representatives tasked with forecasting demands based on initial product releases etc.. All these individuals work together in order create attractive packages that convey key messages about brand values while providing necessary information required by law prior consumer interactions occur.

Overall, packaging design is an important component during new product development phases which requires careful consideration related issues such as target audience preferences, legal requirements regarding labeling/warning symbols etc.. Companies must leverage experienced professionals from fields such as engineering, graphic design, law etc., in order properly execute this step prior moving onto subsequent ones within launch timelines if they want successful results upon entering respective markets worldwide.

The average new product development costs in the testing and certification phase spans from $2,500-5,000.

MOLD TOOLING AND MANUFACTURING SETUP - PHASE 8 OF NEW PRODUCT DEVELOPMENT

Mold tooling and manufacturing setup are important steps for new product development as they determine how the final product will look and function. The process consists of a number of stages, beginning with designing the mold, or ‘die’ which is used to shape the part and then proceeding to the production stage when metal and plastic are injected into the die to create parts that have uniform dimensions. During this step, companies must consider factors such as material selection, tool life expectancy and any potential shrinkage which could occur during cooling times. In order to ensure that each component is made accurately according to exact specifications, companies often use computer-aided design (CAD) software to create virtual models of proposed products before progress is made on physical prototypes.

In addition to creating molds, companies must also invest in machines capable of performing injection molding operations. These machines come in various sizes and require specialized fixtures depending on the type of material being processed; however some types can be repurposed for multiple jobs depending on specific demands. To further optimize operations, automated systems can be employed which allow for reduced labor costs over long-term cycles by introducing robotic technology into assembly lines for increased efficiency.

When manufacturing components using molds in volume amounts, it is also necessary to consider associated costs related to wear-and-tear on equipment over time; these include items such as lubrication agents which help prolong tool life expectancy while still maintaining optimal levels of performance. Furthermore, companies should also factor in expenses related periodic maintenance activities which keep machines running at peak levels while helping reduce downtimes due unexpected malfunctions from occurring frequently. In some cases this might mean investing in spare parts inventory so emergency repairs can be conducted quickly without relying too heavily on external vendors or third-party suppliers.

Overall, mold tooling and manufacturing setup are integral steps in new product development since they provide direct control over how a finished item looks/functions prior release into respective markets worldwide. Companies must leverage experienced professionals from fields such as engineering, tooling technology and machine automation etc., in order properly execute this step efficiently if they want successful results upon entering respective markets worldwide.

The average new product development costs in the tooling and manufacturing setup phase span from $10,000-100,000+.

PRODUCTION BATCHING AND MINIMUM ORDER QUALITY - PHASE 9 OF NEW PRODUCT DEVELOPMENT

Production batching and minimum order quality are two important steps in the process of bringing a new product to market. Batching is the process of grouping components or units into batches for production purposes. This helps achieve cost savings on labor and materials, as well as ensuring that each item meets quality control standards before being released for sale. Minimum order quality is a process whereby manufacturers set a minimum standard for an order to be accepted by them; this is done in order to ensure that all parts produced meet their specifications and customer requirements.

Batching allows companies to group similar components together, thus reducing the amount of time spent on assembly line operations and minimizing wastage due to defects or incorrect orders being shipped out. It also enables manufacturers to use resources more efficiently by allowing them to identify which products are most profitable and how many pieces should be produced in each batch run. The benefits go beyond just cost savings; batching can lead to improved productivity, increased customer satisfaction, and better inventory control.

Minimum order quality helps ensure that any components or parts produced meet customer requirements and industry regulations for safety and performance. It helps prevent defects from occurring during production, which could potentially lead to costly recalls or unsatisfied customers if not caught early on. Manufacturers will often specify certain criteria such as material thickness, surface finish, tolerances, etc., which must be rigorously tested prior acceptance into an order; this is done in order to guarantee a consistently high-quality product every time.

In summary, production batching and minimum order quality are essential steps when creating a new product for commercial release; they help control costs while also guaranteeing high-quality products that adhere to both industry regulations as well as customer expectations. By leveraging experienced professionals from fields such as engineering, manufacturing technology, logistics etc., companies can effectively manage these processes while still staying within launch timelines if they want successful results upon entering respective markets worldwide.

The average new product development costs in the production batching and MOQ phase span from $25,000 upwards, depending on order size.

SHIPPING AND IMPORT COSTS - PHASE 10 OF NEW PRODUCT DEVELOPMENT

Shipping and import costs can have a significant impact on the overall budget of delivering new products to market. In order for companies to be successful in their product launches, they must factor in these costs when planning their budgets.

When it comes to shipping and imports, one of the biggest factors that affects cost is the distance between production facilities and end customers. Shipping by air or sea can become quite expensive depending on how far away the destination is. Also, there are additional fees associated with customs clearance, taxes, duties and port charges that must be considered when calculating shipping costs. Furthermore, some countries may also impose import quotas or regulations that could raise overall expenses as well.

Once the product arrives at its destination, businesses may incur additional costs such as storage and distribution fees. Companies may need to rent storage warehouses or other facilities if they are unable to store items within their own premises. Once products arrive at their respective warehouses, there will be further expenses incurred due to labor needed for unloading and sorting goods after arrival. There are also transportation fees associated with transporting from warehouses to retail stores or other final destinations where customers will purchase them.

All of these costs must be taken into account when planning a company's budget for new product launches in order increase their chances of success in the global marketplace. Moreover, companies must also plan ahead for any potential delays that could occur during transit due to natural disasters, strikes or other unforeseen circumstances since this could have detrimental effects on timelines and budgets if not properly managed before launching a new product worldwide.

The average new product development costs in the shipping and import phase span from $5,000 upwards, depending on order size and can also apply to prototypes.

SUMMARY OF NEW PRODUCT DEVELOPMENT COSTS

New product development costs are an essential part of launching successful products in the global marketplace. Effective management of this process requires experienced professionals from fields such as engineering, manufacturing technology, logistics etc., that can help control costs while still staying within launch timelines for successful results.

Overall, there are numerous factors involved when creating a new product for commercial release which could lead to costly deficits if not taken into account during planning stages. By leveraging experienced professionals from multiple disciplines and keeping an eye out for unexpected expenses such as storage fees and transportation costs, companies can ensure their chances of success upon entering respective markets across the globe are much higher than without proper management of these processes beforehand.

New product development costs

Schedule an initial talk and get to know us better! You already have a basic brief? Send it over so we can have a more productive first meeting!

a meeting