- Mindsailors

- Services

- Prototype manufacturing

Prototype manufacturing services for all product development stages

Prototyping is an essential step in the product development process that allows to turn concepts into actual, testable, and manufactured goods. Prototyping accelerates projects, pushing boundaries and ensuring that each design phase is meticulously validated. Our approach integrates the latest technologies and materials to produce accurate, cost-effective prototypes that meet the unique needs of every project. Defining a prototype can help to understand further paragraphs so what exactly is a prototype? Well a prototype is an early sample model, or release of a product built to test a concept or a process. In that very definition we have testing, exploring, and something that's not finished yet.

A Prototype for Every Project Phase

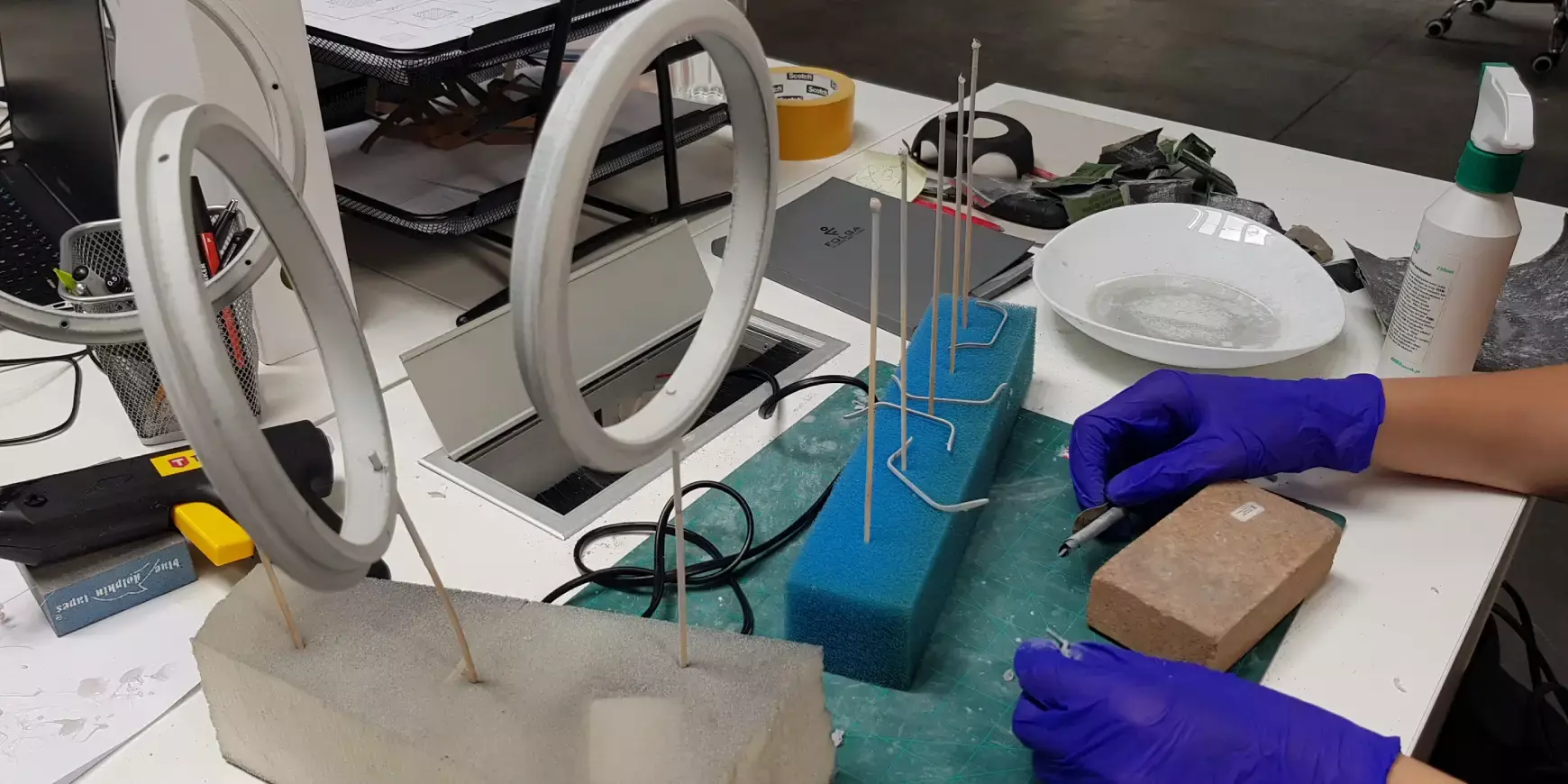

During the initial stages of product development, we create proof-of-concept prototypes. These early, low-fidelity models—often made from materials like cardboard, foam, or paper—allow us to rapidly test and validate the feasibility of product concepts. Using technologies such as 3D printing and laser cutting, we can quickly bring ideas to life and explore their potential. We would like to know if our concept is doable. So we're making a physical proof of how to put together basic ideas or basic principles of mechanisms of electronic components that will eventually build up to a concept that we want to develop. This type of prototyping helps us to validate an idea.

As the design evolves, we develop functional prototypes. These are more refined models, crafted from robust materials like plastic or metal, allowing us to test the product's functionality and make necessary design iterations. Functional prototypes are typically produced using CNC machining or injection molding, ensuring they closely resemble the final product in terms of usability and durability.

In the final stages, we create pre-production prototypes. These prototypes are nearly identical to the final product and are used to test the design in real-world conditions, identifying any last-minute issues before mass production begins. We employ advanced technologies, such as vacuum casting and precision CNC machining, to produce these prototypes, ensuring they meet the highest standards.

All of the above shows that prototyping, which is a very broad term, already has at least three levels: the level of validating the idea, the level of validating looks, and the level of executing functionalities and improving the design,

Prototyping techniques

While traditional methods like sculpting with clay and paper still play a role, modern advancements have brought a host of more sophisticated techniques into the spotlight.

3D Printing

It has become one of the most popular prototyping techniques, thanks to its affordability and accessibility. Today, even hobbyists can own small 3D printers for everyday projects. However, in industrial design, 3D printing is used at a much higher level, utilizing advanced technologies to create detailed prototypes that allow designers to test and refine their ideas with precision and without the need of tooling.

CNC Machining

CNC (Computer Numerical Control) machining is an older but still vital technology in prototyping, especially when working with sheet metal. Modern lasers have reduced the need for expensive tooling, allowing designers to cut intricate shapes quickly and efficiently. While the cost per piece might be higher, the ability to rapidly prototype and test without extensive tooling is a significant advantage.

Welding and Metal Processing

When prototypes require structural integrity, such as in furniture or equipment design, welding and other metal processing techniques come into play. These methods allow designers to create robust prototypes using the same materials as the final product, ensuring the prototype can withstand real-world forces and stresses.

Craftsmanship and Finishing Techniques

Even in the age of advanced technology, traditional craftsmanship techniques like clay modeling, paper sculpting, and foam carving remain essential. These methods allow for quick, hands-on experimentation and refinement. Additionally, finishing techniques such as sanding, painting, and chemical vapor deposition are crucial in giving prototypes a polished, realistic appearance, simulating final production quality.

In the world of industrial design, combining these advanced and traditional prototyping techniques allows designers to explore, test, and perfect their creations, ensuring that the final product is both functional and aesthetically pleasing.

Prototyping: A Critical Validation Process

Prototyping at Mindsailors is not just about creating models; it’s a rigorous validation process integral to the success of the final product. Whether it's testing the feasibility of an idea, refining a design, or preparing for full-scale production, our prototypes play a crucial role in bringing your vision to life. With our extensive expertise and state-of-the-art tools, we ensure that every prototype, from proof-of-concept to pre-production, is a step towards delivering a product that is both functional and visually appealing.

A prototype is an object that does not have a production line, but it helps all the engaged parties—the manufacturers, the client, and the designers—to work towards implementing a planned product. If you want to know more about prototyping in industrial design world, consider listening to our podcast: Prototyping in product development - IDology #2 - Industrial Design Podcast

Prototype manufacturing

Schedule an initial talk and get to know us better! You already have a basic brief? Send it over so we can have a more productive first meeting!

a meeting