This project highlights the continuation of a long-lasting partnership with the POTZ brand. Our client proposed an unconventional watch winder that provides a gyroscopic motion which reflects the natural movement of a wrist, that would normally wind a self-winding watch. The mechanism is well known among high-end watch winders, but in this case, we have added a rotating motion allowing us to wind the watch in an (almost) vertical position.

The aesthetics of the outer shell strongly correlate with the automotive industry, while the form looks towards high-quality audio equipment. All of this creates a unique product.

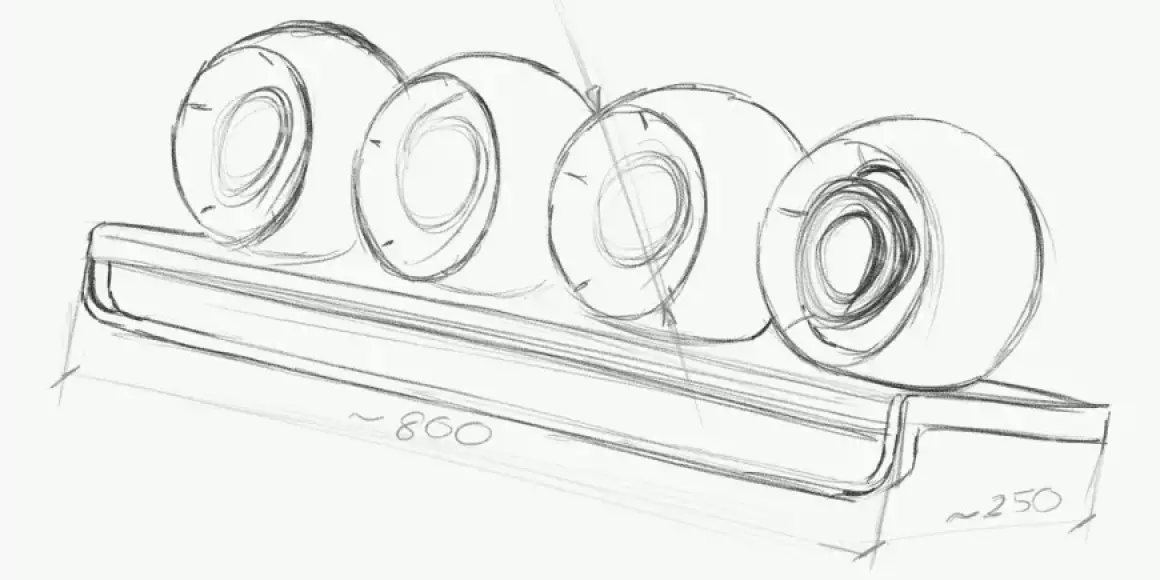

The final user can choose a version with 1, 2, 3 or 4 cassettes. Suppose they previously owned a version with fewer cassettes. In that case, they can send their product back to the manufacturer for an upgrade and receive a watch winder with more cassettes by paying less than purchasing a brand new product.

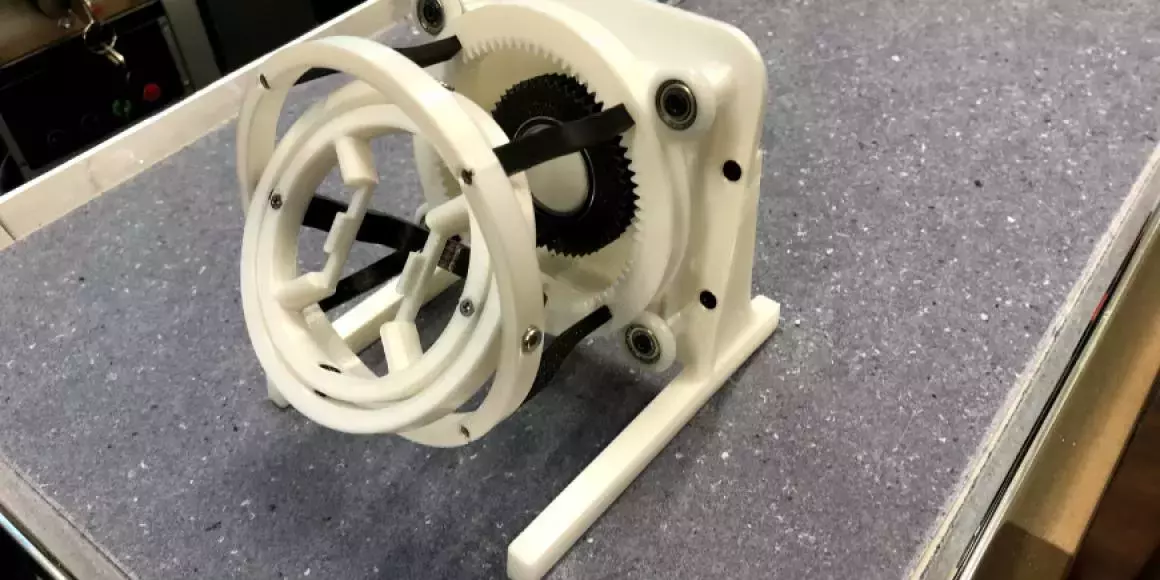

In this case, the proof of concept was essential for further work. We had to check whether an idea in the form of a simplified 3D model would actually work. Several trials and rapid prototypes gave us confidence that this was a challenging but worthwhile route to explore. Based on these prototypes and knowledge from previous projects, we prioritised the functionality and defined the size of watches compatible with the cassettes we intended to design.

The challenge was great because the client already had a well-defined style based on an earlier product. The added modularity feature opened up new possibilities and resulted in three different conceptual directions. One of these was based on the original Genesis design, and it was this version that the client decided to develop further.

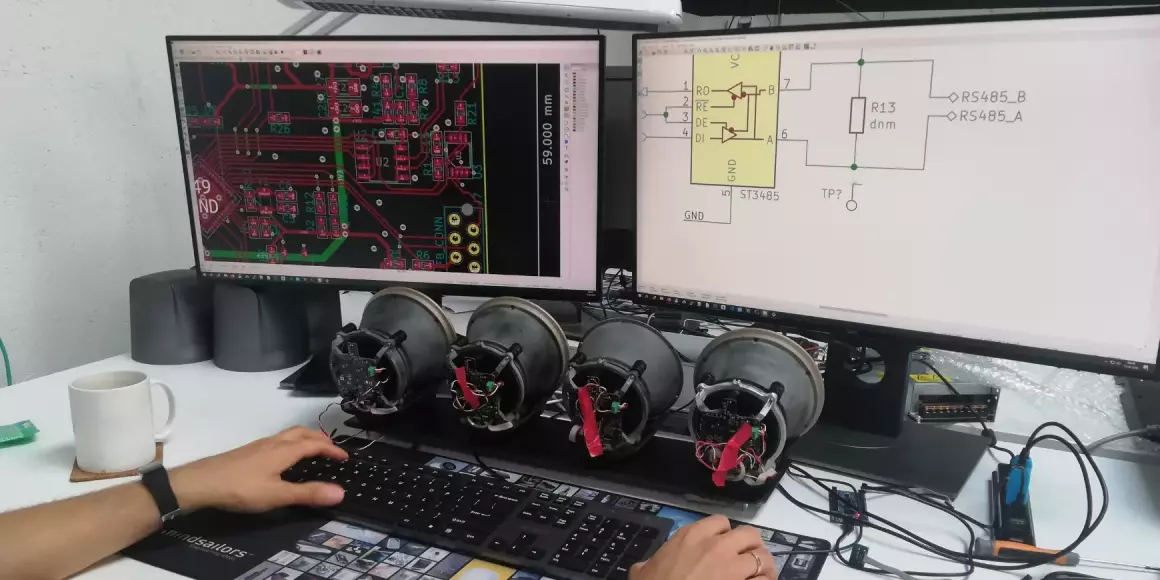

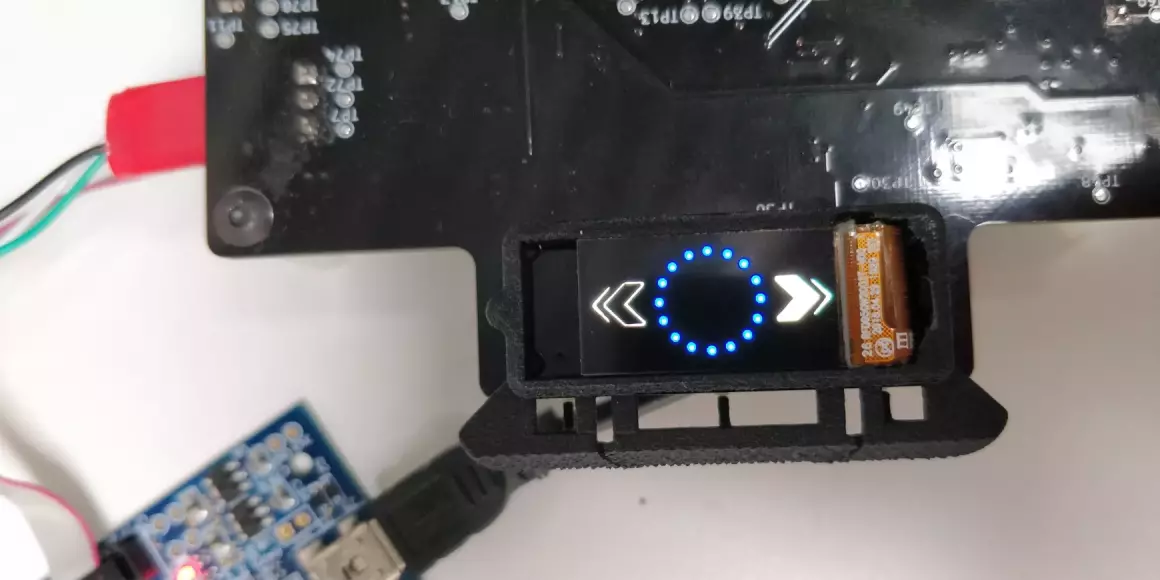

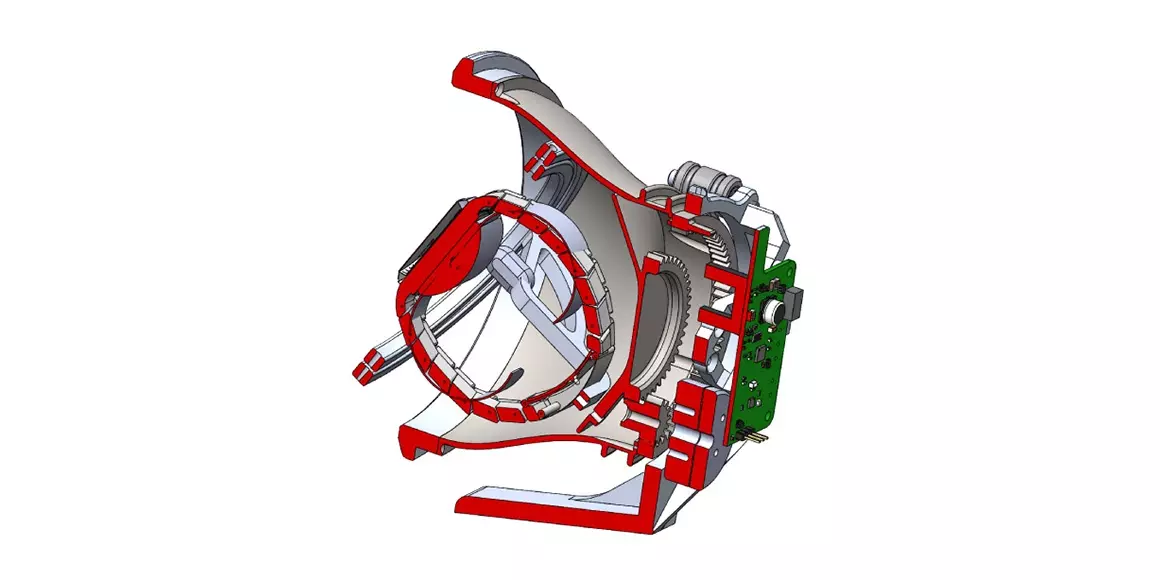

We worked through the details, discussing product functionality, cassette controls and electronics. We considered which button layout would be most beneficial and developed the cassette's final form along with the tabletop mounting feature.

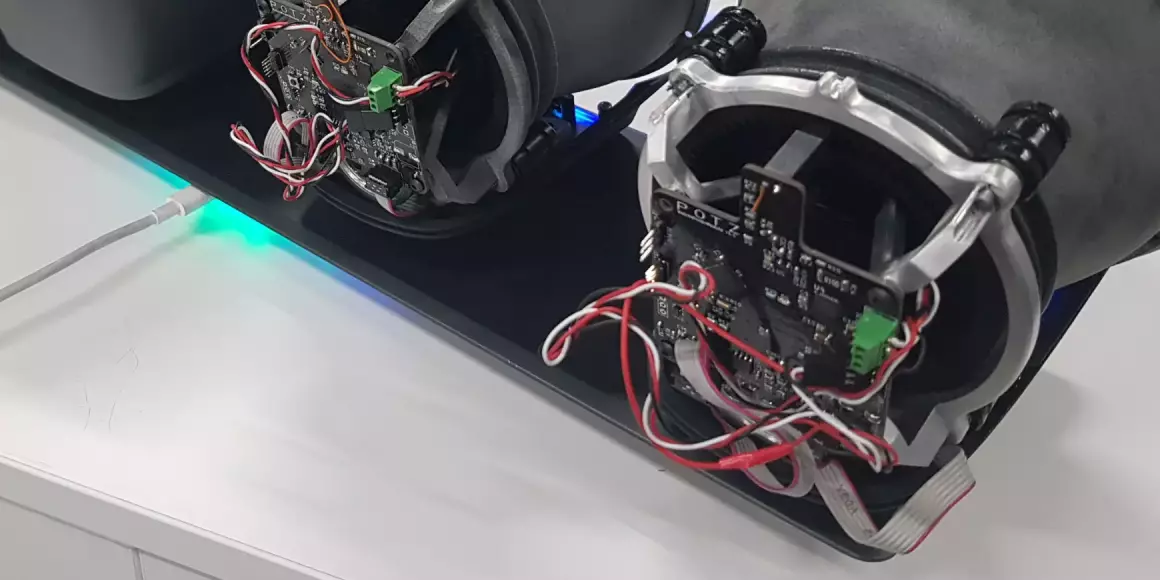

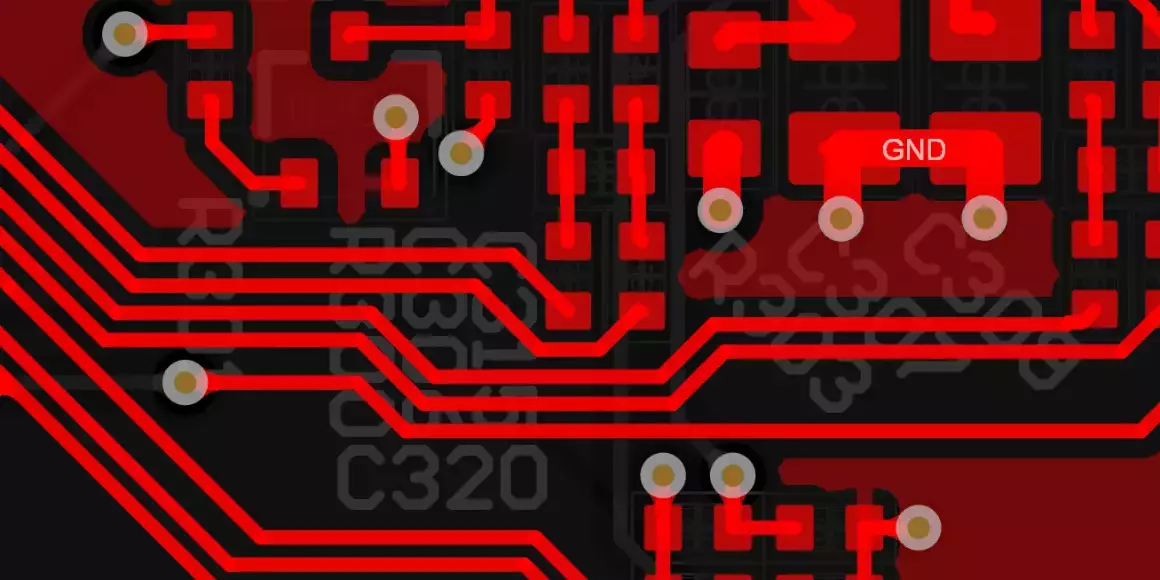

We spent a lot of time refining the final surfaces of the cassette model. But before that could happen, we had to choose the right motor drive and find the right place to put it. Initially, we tried to use the motor from the original Genesis model, but the compact design of the cassette did not allow us to place it in the right place. We turned to a brushless motor, which proved the perfect solution. The small size, high torque and holding capacity meant that more advanced mechanical design could be carried out, including the design of the motor support frame, electronics and moving rings. We developed a transmission mechanism that gave us exactly the movement we wanted while hiding the moving parts behind a neatly finished interior. The end result of this phase was a mechanical prototype that looked like the finished product. Of course, many aspects still needed refinement, but we successfully verified the basic assumptions.

for manufacturing

We created a so-called golden sample - a prototype that accurately reflects the final materials and assembly tolerances. We also prepared technical drawings and technological documentation so that the client had all the information necessary to start looking for production partners.

supervision

The client collected the golden samples and progressed into production.

The project highlights the continuation of a long-lasting partnership with POTZ brand. The client proposed an unconventional watch winder with a gyroscopic motion, reflecting the wrist's movements during the everyday use of a self-winding watch. The mechanism is well known among high-end watch winders, but in this case, we have also added rotating movement so that the watch can be winded in an (almost) horizontal position.

Every product design is the result of a team effort. It never boils down to one person, but every project has its lead designer or lead contributors. If you want to know more about our current team, visit our team page.

Schedule an initial talk and get to know us better! You already have a basic brief? Send it over so we can have a more productive first meeting!

a meeting