- Mindsailors

- Blog

- industrialdesign

- Product Design Process: What is it and how does it relate to product development?

Creativity is the key to successful product development. But how do we unlock it? The answer lies in the product design process. This process involves creating and developing concepts, product designs, and prototypes that meet the specific needs of a company or industry. It's an iterative process, often requiring multiple rounds of revisions before a final product is ready for launch. By understanding the product design process and how it relates to product development, you can unlock your product's potential and revolutionize your product development journey.

WHAT IS THE PRODUCT DESIGN PROCESS?

Incorporating a product design process is a critical step for any company or industry looking to create and develop successful products. It requires an understanding of the specific needs of the company or industry and an iterative approach to refining and perfecting product designs that meet those needs.

The product design process is a method of product development that involves creating and developing concepts, product designs and prototypes. It organizes development stages and communication, it optimizes financing and scheduling, and greatly improves deliverability, and overall understanding of a project.

Through the product design process, designers and engineers can collaborate to explore different ideas, materials and technologies until they find the best solution for their product. This approach allows for greater flexibility in the development process as it encourages experimentation with different ideas and designs. Furthermore, it allows for a more efficient product development process as designers can quickly identify potential problems and correct them before moving onto the next stage.

WHAT'S THE DIFFERENCE BETWEEN PRODUCT DESIGN AND INDUSTRIAL DESIGN?

The product design process, in principal, is the same thing for industrial design, and is just as important. Theses processes overlap just as industrial design and product design overlap. And that's the hard question. What's the overlap? What's the difference?

The difference between product design and industrial design lies in their scope, focus, and the stages of development they emphasize, although both overlap and often work hand-in-hand. Here’s a breakdown of the two:

Product Design

- Focus: Product design is centered around the user experience and the functionality of a product. It involves creating products that meet specific user needs and solve problems. The design process includes considerations for usability, aesthetics, and interaction with the product.

- Main Responsibilities: Product designers often deal with features like ergonomics, functionality, and appearance. They ensure that the product is easy to use and meets customer expectations in terms of performance and convenience.

- Examples: Consumer electronics (like smartphones), furniture, tools, or software interfaces.

Industrial Design

- Focus: Industrial design is broader and covers the overall design and manufacturing process of products that are intended to be mass-produced. It deals with creating products that are not only aesthetically appealing and functional but also feasible for large-scale production.

- Main Responsibilities: Industrial designers consider materials, production methods, and cost-efficiency. They collaborate closely with engineers and manufacturers to ensure that the product can be efficiently produced at scale, taking into account things like production constraints and sustainability.

- Examples: Household appliances, cars, industrial machinery, or medical devices.

Key Differences

- Scope: Product design focuses more on how a product functions and serves the user, while industrial design encompasses the entire process, from aesthetics to manufacturability.

- Scale of Production: Product design may focus on custom, one-off, or limited-run products, while industrial design typically focuses on mass production.

- Collaboration: Industrial designers often work more closely with engineers and production teams to ensure that a design can be produced efficiently and cost-effectively.

In essence, product design zooms in on the user experience and functionality, while industrial design takes a broader look at manufacturability and production efficiency for mass-market products. Both disciplines are crucial to bringing successful products to market.

WHY IS THE PRODUCT DESIGN PROCESS IMPORTANT FOR PRODUCT DEVELOPMENT?

The product design process is essential for successful product development. It provides a structured approach that simplifies experimentation and innovation while also ensuring that all stakeholder needs are met. By using this process, designers and engineers can work together to create products that are aesthetically pleasing, cost-effective, and functional.

Furthermore, the product design process allows companies to test their products in a realistic environment before launching them to the market. This ensures that any potential problems can be identified and corrected before they become an issue. The iterative nature of the process also allows for quick revisions and adjustments as needed, resulting in a more efficient product development process overall.

UNDERSTANDING THE DIFFERENT STAGES OF THE PRODUCT DESIGN PROCESS

In order to make the most of the product design process, it's important to understand the different stages involved. We have developed our own version of the process, and generally speaking, it is divided into six main stages:

1. Pre-design

The Pre-design stage is the first step in our product design process and involves understanding the project's needs and requirements. During this phase, our designers will research existing products and technologies to gain a better understanding of what works and what doesn't work. They will also consider user feedback, customer preferences and market trends. This research helps designers form an understanding of the product they're designing before beginning development.

To make it interesting, we use the information we gather to challenge our clients brief. This might be a verification, or a condratiction of our clients plans or assumptions, as to what should or should not be implemented or considered for the project. Usually it's a mix of both.

2. Conceptual Design

The Conceptual Design phase is the second step in our product design process and involves creating ideas for the product. During this stage, designers will brainstorm, sketch and create concepts for the product. This helps them gain an understanding of how the product should look, feel and function. The aim of this phase is to come up with creative solutions that meet user needs while also being cost-effective and aesthetic.

It is important to be aware that the final form of a product will most definately, to some degree be different from what the designers envision at this stage. It might be due to customer feedback, or for practical reasons related to manufacturing, that are impossible to predict at this stage.

3. Targeted Conceptual Design

The Targeted Conceptual Design stage is the third step in our product design process and involves refining and developing the chosen concept. During this stage, designers will focus on finding solutions that are both functional and aesthetically pleasing. They will also consider how to use different materials and technologies to create a product that meets customer needs while staying within budget.

This stage is a narrowing down of what was developed in the previous stage. One of the concepts is being worked on in detail, and with additional feedback from the client. This is not yet a stage for prototyping, but for giving the initial visions a more realistic shape and form.

4. Mechanical Design

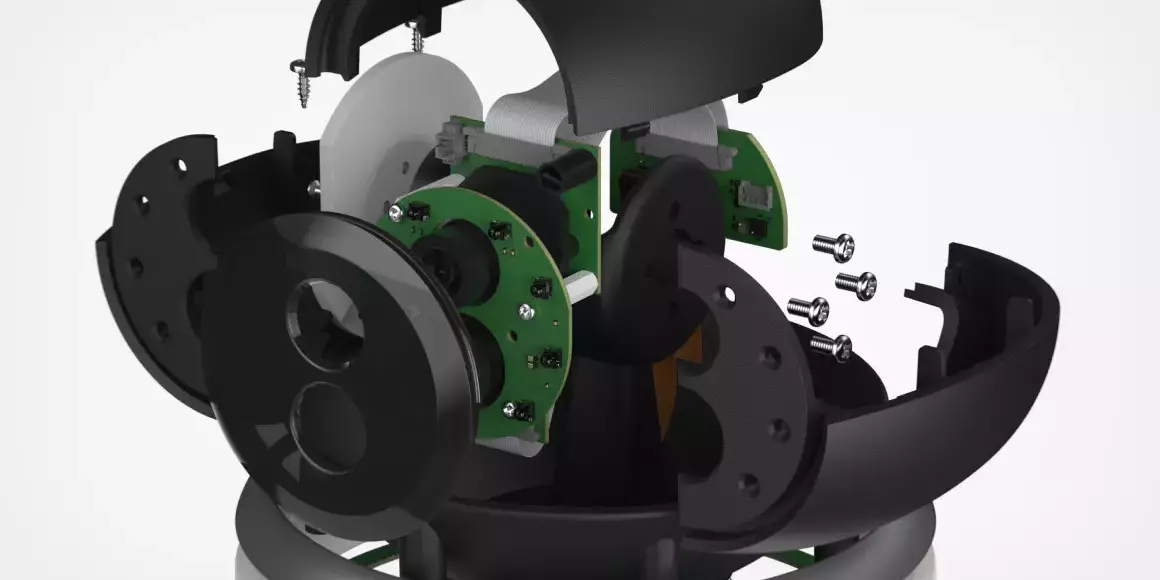

The Mechanical Design stage is the fourth step in our product design process and involves developing a detailed plan for how the product will be put together. During this stage, engineers will use CAD (Computer Aided Design) software to create a 3D model of the product. This helps them visualize how all of the components will work together and ensures that everything fits properly.

Usually this is the stage where CAD comes into play, but at Mindsailors we actually use CAD software from the very early stages of visual design work. Why CAD software shines in mechanical design is because this stage is more related to engineering then what you would commonly consider as "product deisng". It involves "designing" the shell, mounting, ribs, and the both proverbial and literal "nuts and bolts" of the product.

5. DFM - Design for Manufacturing

The Design for Manufacturing stage is the fifth step. It involves optimizing the product’s design for cost-effective manufacturing. During this stage, engineers will consider factors such as production cost, lead time, quality control, and scalability to ensure that the product can be manufactured efficiently and affordably.

This stage involves close co-operation with a chosen manufacturing facility. Ideally we have one chosen way before this stage, but even if one comes into play only now, we still need their engineers and production managers inputs to make sure we optimize the mechanical device of the design, to their manufacturing capabilities. They often have practical experience that can help optimize the project even further in general, e.g. by changing the dimensions, thickness or radii of some elements.

6. Production Supervision

The Production Supervision stage is the sixth and final step in our product design process. During this stage, our engineers will oversee the manufacturing process to ensure that the product meets all specifications and quality standards. This helps maintain consistency across products and ensures that each one meets user needs.

This stage is quite important, as only after the first batch of components comes out of the manufacturing facility, can we verify wether our mutual optimization efforts were indeed fruitfull or not. Sometimes it turns out that not everything works as planned, and it's neccessary to figure out what went wrong, and how to fix it. As at this stage not a lot can be done with a limited budget, it is crucial for a consulting company to work as an expert moderator between the manufacturing facility and the client.

THE BENEFITS OF USING A PRODUCT DESIGN PROCESS

The product design process provides companies with a systematic approach to product development that has multiple advantages. Here are some of the key benefits of using the industrial design process:

- Faster Development: The iterative nature of the process allows for quick revisions as needed, resulting in more efficient product development overall. This helps businesses get their products to market faster and make adjustments if needed along the way.

- Reduced Development Costs: By using the industrial design process, companies are able to reduce development costs by streamlining and optimizing the product design process. This helps businesses save money and stay on budget while still creating a high-quality product.

- Improved Quality: Companies can ensure that their products meet user requirements and stand out from the competition with an effective industrial design process in place. With this system, businesses are able to create innovative products that meet customer needs while staying within budget.

CONCLUSION

The product design process provides companies with a systematic approach to product development. It involves creating and developing concepts, product designs and prototypes that meet the specific needs of a company or industry.

The process is iterative and can involve multiple rounds of revisions before a final product is ready for launch. Companies need to take into account all phases including conceptual design, targeted conceptual design, mechanical design, design for manufacturing (DFM) and production supervision. With an efficient system in place, businesses can elevate their product from concept to reality quickly and effectively.

The product design process provides a great way for companies to not only meet customer needs but also ensure that their product stands out from the competition. Investing in developing a product design process that best fits your team, or products, is an essential step for any organization looking to deliver successful products and services.

Product Design Process: What is it and how does it relate to product development?

Schedule an initial talk and get to know us better! You already have a basic brief? Send it over so we can have a more productive first meeting!

a meeting